| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | VOBEN |

| Model Number : | 16-30 Mesh,30-60 Mesh, 200 Mesh,Grade III |

| Certification : | ISO9001 |

| Price : | US$220-600/MT FOB Qingdao |

| Payment Terms : | Western Union, L/C, T/T |

| Supply Ability : | 50,000-100,000 Mts Per Year |

| Delivery Time : | 15days |

Grade III Sintered Mullite Sand and Powder for Precision Investment Casting and Refractory Industry with High-alumina

1. Production Introduction

Mullite is made of kaolin by high temperature sintering. The chemical components of mullite are all chemical substances with strong fire resistance, and their properties are relatively stable.

It mainly includes: alumina, silica, etc., the content of alumina is between 42% and 46%, and the content of silica is between 51-53%. In addition, there are less substances: iron oxide, sodium superoxide, potassium superoxide, titanium oxide, magnesium oxide, etc

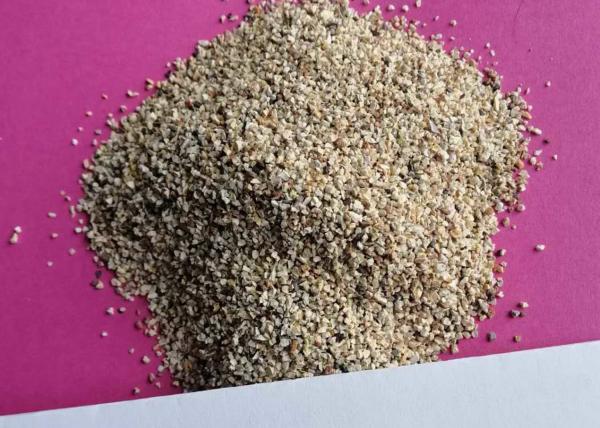

a. 16-30 Mesh Grade III

30-60 Mesh Grade III

200 Mesh Grade III

Grade III

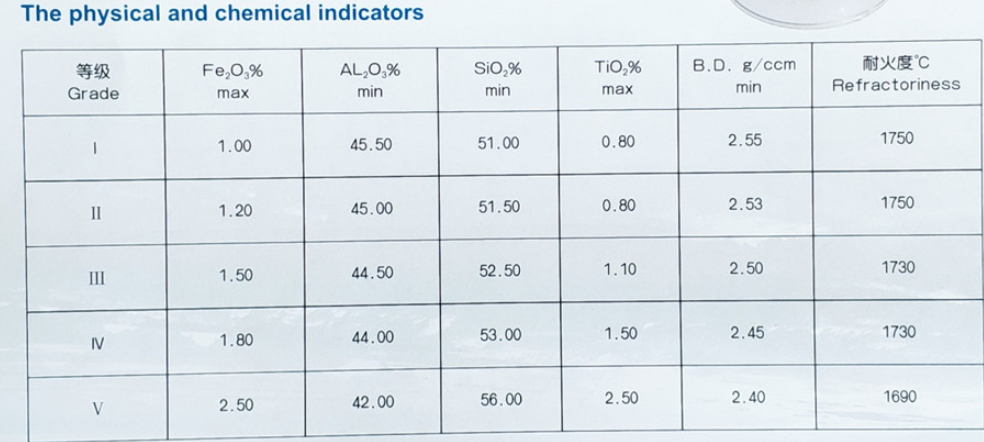

2. The Physical and Chemical Indicators of Sintered Mullite Sand and Powder

3. Sintered Mullite sand and Flour Application:

Sintered mullite sand and flour is widely used in investment casting, gypsum filling V method and vacuum suction casting, as well as large, medium and small steel casting, copper casting, furnace lining refractories, as well as water glass, refractory products, concrete materials, etc.

Widely used in machinery, aviation, weapons, metallurgy, petroleum, heat preservation, sintering, construction and other industries

For Shell-making

4. About Us

Our company is located in No.62, Beijing Road, Qingdao Bonded Port, a beautiful coastal city. It is backed by Qingdao port and only half an hour away from Qingdao New International Airport. The convenient traffic conditions provide the favorable conditions for the company's development.As the strategic partner of mining plant,we focusing on the development of domestic and foreign precision casting and refractory industries.With the professional processing line and experienced engineers from mine plant,we can provide high quality products and perfect sevice.

The Calcining Furance

Automotive Process line The Raymond Mill

The warehouse

5. Our Package and Loading

Finished package

|